This article based on Chema Molina, CEO of Frenetic newsletter discusses planar magnetics considerations as it may not be the best optimum solution designers are asking for.

The trend of planar magnetics as the holy grail of magnetics has lasted 30 years. The trend consists of people, usually not magnetic experts, asking for a planar solution to improve their power density. Or teams of engineers, only trying to solve their designs with Planar technologies without considering any other option.

That’s a mistake.

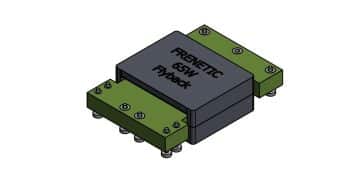

In most cases, the planar solution is not the best, I would say in only 10% of the cases, the planar is the best technical solution for DC/DC magnetics. Inductors are usually the main discussion, so I will focus on transformers and flybacks directly. In the Flyback topology, we have done both cases and to be honest, there was only one case I considered interesting.

When the magnetic is integrated into the PCB from the starting moment. When doing the simulation, you already consider a sizeable parasitic capacitance and use the PCB space considering the winding wires. But in terms of volume, 90% of the cases, you can get a smaller solution and easy to integrate with a concentric magnetic.

For transformers, it depends on the current levels and your mechanical goals. If you consider integrating the magnetic in the PCB, your current levels should be limited to your PCB manufacturer’s copper thickness capability.

For very high current designs, this is entirely different. We don´t use PCB; we use cooper layers and the connection to the power module needs some mechanical solution. Additionally, we use a case to improve the heat dissipation, increasing the weight. In this case, a planar solution is likely more compact.

However, once you are not integrated into the PCB, the height can be achieved using Litz or a combination of Litz and Cooper layers. We saw a good example here in this design completed by Antonio Escudero, in my opinion, one of the best engineers of Infineon.

Integrating Transformer + Inductor

One of the limitations of using a planar transformer is the complexity added in integrating the Leakage inductance as part of the operation. The main reasons are:

- The leakage inductance is low and difficult to predict with more than a 70% accuracy

- You can include some ferrite layers to increase the leakage like in the Total Component article.

There is a significant benefit of the planar designs in this regard: the repeatability, which is extremely good.

Read the original post at To Be Planar or Not To Be