2.1 Coil with ferrite inductors

SMD-Multilayer Inductor

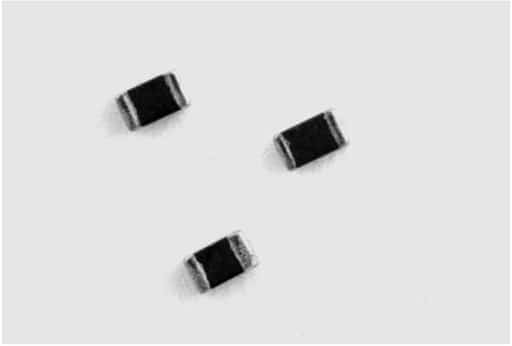

If the wire windings on the outside of a conventional “coil” are mounted inside the coil body, the so-called multilayer SMD inductor (Figure 2.32) is created.

Fig. 2.32: SMD-Multilayer inductor; image source: Würth Elektronik WE-MI

Fig. 2.33: Structural schematics of multilayer SMD inductors

The ferrite body magnetically shields the component, significantly reducing external interference and cross-talk. The multilayer inductor may be seen as a “compromise” between the ceramic inductor and SMD ferrite. This component is especially suitable as an inductor in filters and resonant circuits where low interference from external signals is required and in circuits with high packing density.

Practical tips:

• Do not operate in the self-resonant range

• Observe max. current loading capacity

• Low DC resistance, therefore also suitable for low-voltage systems

Power Multilayer Inductors

Fig. 2.34: Power Multilayer Inductors ; image source: Würth Elektronik WE-PMI

The miniaturization of SMD components, especially inductors, is a widespread trend in portable devices, as it is especially storage chokes that frequently require the most space. Wired components are out of the question in these orders of magnitude. This is where the power multilayer types apply.

In order to allow minimization of the coil volume, the switching controller IC is driven at ever-higher switching frequencies. Switching controllers like the Micrel MIC2285 already work with 4 MHz. The dimensions of the storage chokes required can therefore be reduced by up to 90%. The compact power multilayer inductors in 1008 package (2.5 mm x 2.0 mm x 1.0 mm) not only offer high rated currents (up to 2.4 A), but also a lower DCR than comparable to standard multilayer inductors types.

The saturation current of the power multilayer inductors (such as WE-PMIs) relates to the typical inductance drop of –30% from the zero current inductance. The rated current is defined for the common self-heating of DT = 40 K with respect to the ambient temperature.

Fig. 2.35: Inductance vs. DC current

The used NiZn core material allows the use of the power inductors WE-PMI series up to 10 MHz. The multilayer types are especially suitable for power supplies in portable devices.

Fig. 2.36: Inductance vs. frequency

SMD – Wire Wound Inductor /SMD RF Inductor

The wound SMD inductors (such as Würth Elektronik WE-GF and WE-LQ series) are available in SMD packages (Figure 2.37). They essentially differ in their mechanical construction. Whereas the WE-GF is completely embedded in plastic and can therefore handle high humidity very effectively, WE-LQ is in an open package. It can therefore be loaded with higher currents at the same inductance in relation to its package volume.

Fig. 2.37: Wire Wound Inductor (WE-LQ left) and SMD RF inductor (WE-GF right)

In Figure 2.38 the layout of the SMD RF Inductor is shown graphically. A wire-wrapping surrounds a ferrite body. The special ferrite mixture faciliates a wide inductance spectrum despite the miniature ferrite core.

Fig. 2.38: Inductor construction of resistor-type (WE-GF)

ABC of CLR: Chapter L Inductors

Coil with ferrite

EPCI licensed content by: Würth Elektronik eiSos, Trilogy of Magnetics, handbook printouts can be ordered here.

This page content is licensed under a Creative Commons Attribution-Share Alike 4.0 International License.

see the previous page: Design of optimized EMC filters for real operating environments

< Page 12 >

see the next page: Current compensated chokes