source: EPCI; ESA SPCD 2018 Symposium

EPCI e-symposium library article

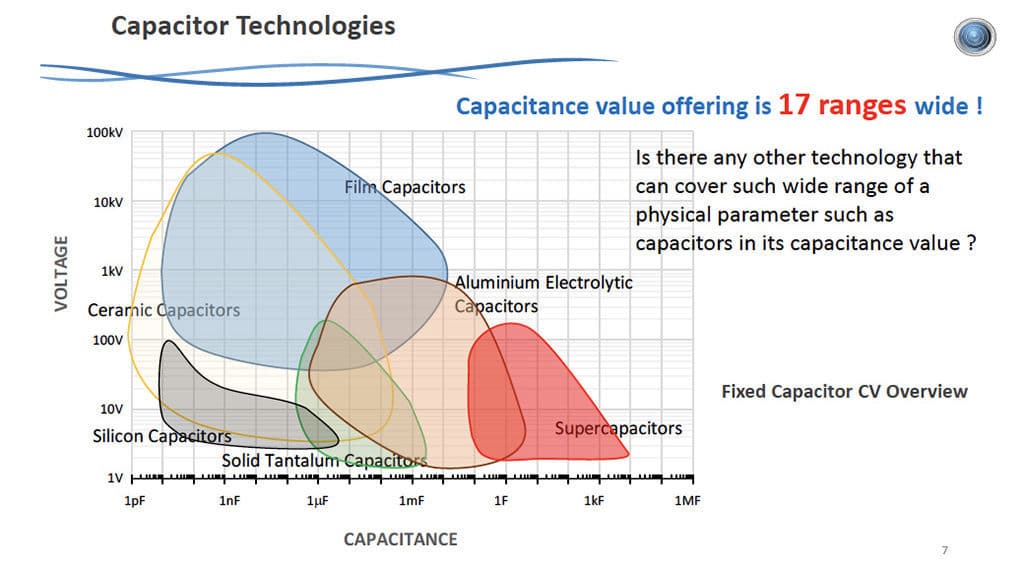

EPCI is continuously collecting passive components news since 2015. The passive component industry is currently going through many challenges facing the new requirements from modern electronics in various applications and directions. On one side, the consumer electronics is moving towards applications such as wearable applications with IoT communication capabilities, supported by the upcoming 5G telecommunication infrastructure, on the other side there are number of demanding new requirements related to energy storage, renewable energies or automotive generation upgrade to EV/ HEV platforms. The paper presents a collection of commented year back selected capacitor headlines that provides a great illustration about the recent directions in capacitor technologies by manufactures’ press releases and pushed articles.

published by EPCI under approval of ESA SPCD 2018 organizing committee.

Title: Capacitors News and Trends

Author(s): Tomas Zednicek, Ph.D.

Organisation(s): EPCI, European Passive Components Institute, Lanskroun, Czech Republic

Symposium: ESA SPCD 2018

Reference: Technology Roadmaps 2.

ISBN: N/A

e-Sessions Applications: Aerospace, Automotive, Industrial, Medical

e-Sessions Scope Components: Capacitors

e-Sessions Topics: Roadmaps

The global passive component trend shows growing investments into development of new processes and materials to introduce completely new generation of passive devices. This includes also investments into manufacturing equipment and technological know-how.

MLCC SMD capacitor technology has been the leader in discrete passive components miniaturisation, where 0201 case size has been already in mass volume scale and smaller case sizes down to 008004 are step by step adopted by consumer electronics production nowadays. The sub 0201 and high CV components ( >1000 dielectric layers per chip) commercialisation was conditioned by a generation move from thick film to thin film technologies.

Thin film is a higher development grade generation compare to thick film, but lower than semiconductor manufacturing technology. The semiconductor technology, however is by far more expensive. Thick film is considered to be cheaper but, on the other hand it is consuming more material that in some cases can result in opposite situation with favourable lower cost for thin film solution. In example, the 2017/18 resistor shortage has caused a high price increase of ruthenium resistive material influencing the chip resistors basic cost structure. MLCC capacitor continuously increase number of layers per chip to get higher capacitance in smaller package and offer the popular values in smaller (and cheaper) package. Thus, in general, we can expect a continuous industry move towards the thin film technologies.

The general recent trends in capacitor (and other passives) technologies can be summarised into the following directions:

- Integration into IC chips

- Embedding and Embroidering

- 3D structures

- New materials and Technologies

- Optimisation of mass volume technologies

- Harsh environment capable robust designs

- Range extension and Downsizing

- High power (lower ESR, ESL …)

- New generation of thin film technologies for higher end applications

- Cost saving

Range Extension and Downsizing

See overview of some capacitors and resistors “World first” features and parameters enhancements released in 2017/18 such as the following highlights:

2018 Capacitors World First Headlights

- Smaller DC link film capacitor

- 100kV film capacitors

- Film foil for temperatures up to 150C

- 1000uF MLCC capacitor 2.5V

- 10uF 100V 3525 MLCC capacitor

- Low ESR soft termination MLCC

- BME MLCC qualified to space

- 175/200C MLCC automotive

- World smallest 008004 MLCC capacitor

- C0G MLCC up to 200C

- 1000V 0603 C0G and X7R MLCC

- Tantalum polymer qualification at automotive or aerospace environment

- 30G vibration ready aluminium capacitors for automotive

- Glass to aluminium seal suggests Al El and Supercap reliability enhancement

- 85C 2000hrs and 85/85 1000hrs ready supercapacitors

- 3V (LiIon coin battery) ready thin supercapacitor

- Stretchable and flexible supercapacitors

- Up to 150C or down to -80C capable supercapacitor

- Reflowable chip supercapacitor

- Supercapacitor under space qualification

…. read more at the pdf paper and presentation file link below …

SUMMARY AND CONCLUSION

Capacitors are one of the critical components needed for any electronic hardware designs. We are living in a challenging time with several end market changes and new technology developments on both component and end application sides. Some of the latest trends in capacitor technology and end application market has been demonstrated in this paper using a 2017/2018 capacitor news headlines.

In short summary, the current and future capacitor challenges are related to its core function – energy storage. Generation, recuperation, transportation, transmission and storage of energy from nano-scale up to high power storage networks are among the key topics for today’s electronic and even human society evolution…. from wearable energy harvesters, through electric vehicles to handling of energy generated by renewable sources.

REFERENCES

- Nano Dimension 3D PCB printer Dragonfly 2020.; company website; https://www.nano-di.com/

- Nano Dimension press article.; “Nano Dimension embeds components in 3D printed PCBs”.;https://passive-components.eu/nano-dimension-embeds-components-in-3d-printed-pcbs/ January 2018

- Navratil.J; Soukup.J.; ”Aerosol jet printing technology opportunities”.; https://passive-components.eu/aerosol-jet-printing-technology-opportunities/; 1st PCNS EPCI conference, September 2017

- Blecha.T.; et all.; “Printed and embroidered electronic passive components.”; https://passive-components.eu/printed-and-embroidered-electronic-passive-components/.; 1st PCNS EPCI conference; September 2017

- Zednicek,T. 1st PCNS EPCI Conference, Brno Czech Republic, Sep 2017. “Commercial versus COTS qualified passive components in space applications”.,https://passive-components.eu/commercial-versus-cots-versus-qualified-passive-components-in-space-applications/

- Friedlader, D., web article; “The use of COTS components in space debunking 10myths.”; https://passive-components.eu/the-use-of-cots-components-in-space-debunking-10-myths/; July 2017

ACKNOWLEDGEMENT

The presented paper was prepared under ESA Contract: 40001210761/17/NL/CRS with European Passive Components Institute s.r.o. “Passive Component Support EEE331”

read the full technical paper in pdf here:

and presentation here: