by: Dr. Leo Farhat and Dr. Denis Lacombe; ESA ESTEC; The Netherlands

presented by D.Lacombe at the 2nd PCNS 10-13th September 2019, Bucharest, Romania as paper 3.1.

ABSTRACT

More and more space missions are or are willing to use COTS EEE parts in their projects. Several working group in ESA and outside of ESA are trying to define a standardise way to procure such type of part for space applications. This presentation will try to present a status of the different working groups positions and the consequence for the procurement of passive EEE parts.

NEW SPACE AND COTS

COTS components are mainly used in these applications. COTS are, today, rarely used in other types of projects except Telecom.

New Space activities are active in:

• launchers

• constellations

Why COTS ?

There are three main reasons to use COTS components in space projects:

- better performances

- not existing in space QPL range

- COST, with 1/10 of the cost of equivalent space QPL parts

The first two – better performance and QPL list non-existence – are the main reasons for use in all space projects, the lower cost are the main driver for launchers and constellations applications.

Space standards

Today, we have two types of space standardization systems addressing EEE parts:

- ESCC: European Procurement and qualification system (QPL and EPPL)

- ECSS: Q60 series with guidelines for selection and procurement

- Q30 and Q70 series for proper use of EEE parts

- Several other E series

All these standards would be affected by the evolution of the New Space era.

Space standards for procurement of commercial parts:

Can we use AEC-Q200 parts in High Rel. space?

There are several questions to be answered:

• What are the designs of the parts certified according to AEC-Q200 vs space QPL designs?

• What are the reliability data available to space customers and agencies?

• How the manufacturing processes and materials are monitored to ensure that the reliability of AEC-Q200 parts are the same that during certification (PPAP)?

• Can we accept parts without screening? if yes, for what applications?

Is the design of AEC-Q200 parts compatible?

Available reliability data?

AEC-Q200 specifies clearly the tests to be performed and the methods to be used but:

• Reliability data package of AEC-Q200 are not freely available to space customers and agencies

• How the “four corners” defined in AEC-Q200 are chosen with regards to the range of certified products?

Is PPAP assuring a stable reliability level?

For space QPL parts, we have equivalent document that is called PID (Process Identification Document). It defines the design rules, the materials, the processes, tests and equipment used during manufacturing. BUT in addition to this, we request screening tests and a two years maintenance of qualification tests.

PPAP is generally not available for space actors. We expect that in addition to the information contained in space PID we will find some Statistical Process Control that would allow to discard regular reliability tests.

Can we accept parts without screening?

What is the usual screening?

• specific tests like surge current

• short accelerated life test and Is it relevant to remove early failure?

• early failure are not always the same types of failure that long term failure

• What are the types of rejects observed with usual screening?

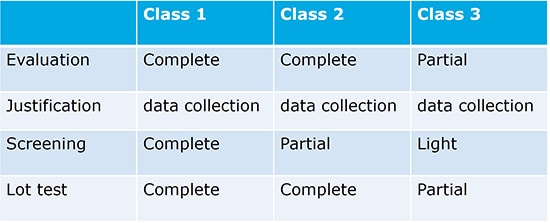

Can we accept AEC-Q200 parts for space projects?

It depends on two main aspects:

1] what are the needs and requirements?

- mission duration

- criticality

- constellation or not

- cost

2] how can we trust our suppliers?

- PPAP

- reliability testing

- audit

- etc?

What can we learn space QPL parts?

Space QPL parts are reliable. Is it too much reliable? For example, ceramic capacitors lifetime 2000 hours life test at 2 times rated voltage at 125C is equivalent to more than 100 years of operational conditions. What does it bring for a “3 years” mission? Do we still need a derating?

Screening is part of space heritage and is mandatory for flights models. It may be now the time to analyse the types of rejects during screening. Is it still relevant as it is defined?

more 2nd PCNS symposium technical papers can be viewed and downloaded in pdf from EPCI Academy e-Proceedings: