This article is based on ESA SPCD 2022 paper entitled “Miniature RF switch for compact redundancy ring” written by Olivier Berenfeld, RADIALL, France, and Olivier Vendier, Thales Alenia Space (TAS), France. The paper was presented during the 4th ESA SPCD conference at ESA ESTEC, The Netherlands 11-14th October 2022 and received BEST PAPER AWARD of the conference. Published under ESA SPCD organisation committee permission.

Introduction

Subject of the activity was to develop Miniature Electro Mechanical Relay (MEMR), a high miniaturization, Surface-Mount Technology (SMT)-compatible, electromechanical switch for the space sector. MEMR can be used within reconfigurable microwave space subsystems in line with satellite evolution toward more digital satellites, which allow high data capacity. The project was founded by European commission under acronym SELECTOR.

Very High Throughput Satellite (VHTS) is the solution to decrease the cost per bit (€/Gbps) of satellite telecommunications. The satellite payload is constituted of a digital core and the digital transparent processor (DTP), which is surrounded by frequency converter units. The number of frequency converter channels in VHTS systems has increased from a few dozens of equipment to several hundred, compared to standard satellite architecture.

As a result, in order to remain competitive without compromising reliability, stronger cost and mass constraints are enforced on such equipment. Redundancy rings are mandatory to achieve an operational lifetime of more than 15 years; however, they are increasingly difficult to implement at a reasonable cost and weight.

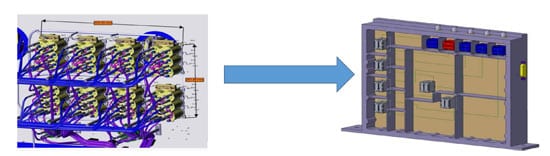

The targeted demonstrator, a VHTS requirement, is a Ka band compact redundancy ring based on SMT to minimize cost and improve integration. The proposal relies on the upgrade of the commercial version to comply with the space environment. A factor of 10 gain in mass is anticipated, compared to standard electromechanical switches.

Objectives

Radiall Objectives:

To deliver space grade MEMR components complying with space constraints and its associated compact redundancy ring application. To achieve the objectives, Radiall engineering team focused on the following MEMR innovative improvements:

- Waterproof (IP 67), to avoid any pollution during cleaning phases

- Microwave performance (DC- 32 GHz)

- Gain in mass compared to existing

- Improve isolation (< – 45dB)

- Harsh environment (random vibrations 50G rms 10 to 2000 Hz, mechanical shocks up to 3000g)

TAS Objectives:

- Use of a new component: Micro Electro Mechanical Relay (MEMR) SMT compatible

- Enable highly demanding connectivity within reconfigurable new generation processed telecom payload

- Compatibility with RF on PCB technology, keeping mass and volume at minimum as compared to standard RF harness complex connectivity matrices H2020 SELECTOR main results

- Patented RF harness connectivity architecture

- Example of redundancy matrix (4:5) addressing wideband requirements from C to Ka band.

MEMR Design

Development was based on Radials existing MEMR Quartz series. This relay has already been qualified for test & measurements and MIL market with significant heritage and return on experience.

IP 67 Waterproof Design

In order to facilitate the cleaning of the soldering area, the MEMR shall meet IP67 waterproof requirements. The unique weakness of this switch about hermeticity against liquid was the RF access. In order to be IP67 we had to adapt the structure of the switch by adding a resin on the insulator. This involved multiple construction changes to optimize glue shape, ridge to prevent glue bleeding, optimize glue thickness and counterbore to facilitate the glue deposit.

RF Performance Improvement

RF ports have been modified to meet new requirements on hermeticity, direction of RF ports had to be adjusted and the whole RF line has been redesigned and optimized.

Some improvements were performed to increase RF shielding effectiveness such as:

- Metallic cap,

- Conductive gasket,

- Shielding of RF access,

- Shielding of Printed Circuit Board

These improvements allow to reach -50dB typical of shielding effectiveness.

Weight Reduction

The cover use of aluminium to improve shielding effectiveness increases the weight that had to be addressed by construction changes. The cover shape has been optimized to remove any un-necessary material. The original cover weight was reduced from 2.05 g to less than 1.23 g.

The RF plate shape was also re-designed to minimize RF body constructional part. Weight decreased from 2.65 g to less than 2.33 g.

Harsh Environment / Vibrations Robustness

Contact pins induce resonance and deform the coil during exposure to high shocks and vibrations. To resist such vibration levels, the coils have to be immobilized.

MEMR Features

MEMR Key Specifications

- SPDT : Single Port Double Throws

- Latching, without telemetry

- Actuation voltage : 6 or 12 V

- Frequency band: DC – 32 GHz

- Weight : 7.5 g

- Dimensions : 15.7 x 13.3 x 12.1 mm

MEMR characteristics are shown in tables below:

Power handling and multipaction based on simulation and test campaigns:

Space Qualification

The MEMR has been subjected to ESA qualification following ESCC generic specification 3603 and detail specification 3603/007. Qualification test according to ESCC3603 was completed at the end of 2022 to be ready for ESA EPPL component level.

First flying mode batch was delivered in November 2022. Target is to achieve ESA QPL level in 2023.

Summary and Major Achievements

New generation of miniaturized microswitch relay MEMR has been developed and qualified to meet requirements for Very High Throughput Satellite (VHTS) new generation of digital satelite. MEMR has been validated in the targeted demonstrator, a VHTS Ka band compact redundancy ring based on SMT to minimize cost and improve integration.

Major Achievements

- MEMR SPDT switch component validating a TRL 6

- Dedicated redundancy ring building blocks validated up to a TRL 6

- I/O interconnects

- SMT mounting of MEMR

- Multilayer RF PCB

- MEMR SPDT demonstration into a compact redundancy ring using RF on PCB technologies available at TAS validating a TRL 3

- Up to 2 redundancy rings 27:30 into the same assembly

- Scalable patented architecture and design

- Wide band frequency

- Performance assessment in C band

- Return loss better than -20 dB

- Less than 3 dB insertion loss between shortest/longest path

- Channel to channel RF isolation better than -65 dB

- Temperature range validation: from -15 to 95 °C

- Good match between measurements and 3D EM RF multiscale models

The next steps include further effort for equipment industrialization and higher frequency operation.