by Paul Svasta, Ciprian Ionescu, Alexandru Vasile, Cristina Marghescu, Bogdan Mihailescu, Andrei Drumea, Norocel Codreanu

University “Politehnica” of Bucharest, Romania, Center of Technological Electronics and Interconnection Techniques, UPB-CETTI

presented by P.Svasta at the 2nd PCNS 10-13th September 2019, Bucharest, Romania as Keynote 4 presentation

Abstract

At the end of the 70s, an electronic passive components manufacturer had used as motto of its products: ”Today the passives are very actives”! This sentence become in our days extremely actual and leads to be mandatory, for development and/or production engineers, to have proper knowledge about the electronic passives components.

Without such knowledge, it become quite complicate, as company, to be competitive in the market of electronic modules. What led to this explosion of passive components diversity and as consequence, for a correct implementation in an electronic circuit, the necessity to identify their characteristics (electrical and non-electrical)? The answer is quite easy to give if we are looking to the actual electronics ubiquity. And what we can observe: today is very difficult to identify any domain, of our life, without electronics.

Of course, this fact requires to be developed passive components able to fulfil requirements for functional safety in extreme various environments. Large temperature domain, large frequency domain, large current domains, large voltage domains, low noise, small package (smaller sometimes as a sand grain!), etc. And we are not able yet to see the impact of the IoT technology. We will present examples of the evolution in the curricula content, laboratories content and work-on, home-works, methods of evaluation and examination and challenges of the future.

I. INTRODUCTION

The Passive electronic components were considered at the beginning of 1990s to be the “poor relative” of the much attractive solid-state components domain. In these unfavorable conditions, at the Faculty of Electronics from UPB was introduced, after the changing of political regime a new lecture named Passive Electronic Components and Circuits (CCP in Romanian), based on the practical experience obtained from a major factory, producer of passive components, IPEE Curtea de Argeş, and with influences from some universities in Germany, for instance TH Darmstadt. It is to mention here the book of Professor Zinke, see [1], which was a guide for us in establishing the structure of the first lectures in passive components. The main purpose of the lecture is to make aware the future Engineers of the huge difference between the theoretical representation of R, L and C and the real components Resistors, Capacitors and Inductors.

We think that the level of knowledge in this domain was continuously increased, maybe a little contribution was brought by CCP. For supporting this idea, we will mention here a simple fact. Twenty years ago, in a distributor shop for electronic components the customer asked “Please give me 10 pieces of 2.2 kilo-ohm resistors” and usually the salesman was coming directly with the plastic bag of resistors saying It will cost you 2 Lei, for instance. From here we can analyze two aspects 1. The customer was very imprecise in asking what to buy. For instance what type of resistors he wants, the tolerance and the rated power, the temperature coefficient and so on. On the other side, these questions should be asked by the salesman, supposing he had knowledge about. So he should ask, do you wish SMD or THD, what type metal film or thick film, what tolerance, what power, do you have a preferred manufacturer, and so on. Nowadays the situation is different. Probable causes are the system of ordering, using on-line and more detailed Bill of Materials required in many practical design, and, we wish to believe, that the general level of knowledge in passive electronic components field was strongly increased.

We wish to introduce the frame of activities related to Passive Components. Our host, University Politehnica of Bucharestis the oldest and most prestigious engineering school in Romania, with a tradition of more than 200 years. Its specificity relies in creating knowledge through research and technological innovation, as well as through implementation of these ideas by means of education and professional training at a European level. At present the University Politehnica of Bucharest is formed by 15 different faculties. One of the largest faculties is Faculty of Electronics, Telecommunications and Information Technology (ETTI).

The Romanian school of Electronics and Telecommunications was set up in 1920 as part of the Polytechnic School of Bucharest. This later developed as a distinct specialization called Telephony -Telegraphy within the Faculty of Electromechanics (1924), which will later evolve as a distinct department called Electrocommunications (1929). The Faculty of Electronics was set up in 1953 as a branch of the Faculty of Electromechanics, including the departments of Electronics, Radiocommunications and Telephony -Telegraphy. Inside the Faculty of Electronics there are four departments, one of them, the youngest one is Department of Electronics Technology and Reliability. This department was founded by Professor Vasile Cătuneanu in 1971, being the first University group oriented toward electronics packaging in Romania. In the frame of department, the research center UPB-CETTI was established in 1995. It was thought as a bridge between education and research, focused in electronics packaging activities. Most of original CETTI founder members are or were involved in activities related to passive electronic components.

Today we consider that the evolution in the field of passive components is oriented toward: reduced dimensions, increase of working frequencies, increase of capacity to dissipate heat and extending of temperature range (special requirements for automotive industry). Simultaneously the users ask for enhancement of stability (with temperature and other environment factors) and increase of reliability. The manufacturers look for diversification of products in order to offer the component specific for each application, if possible at a reduced price. New components as Supercapacitors, or even Memristors are intensively studied. There is also open field for passive components in organic electronics and for the use of integrated passive components.

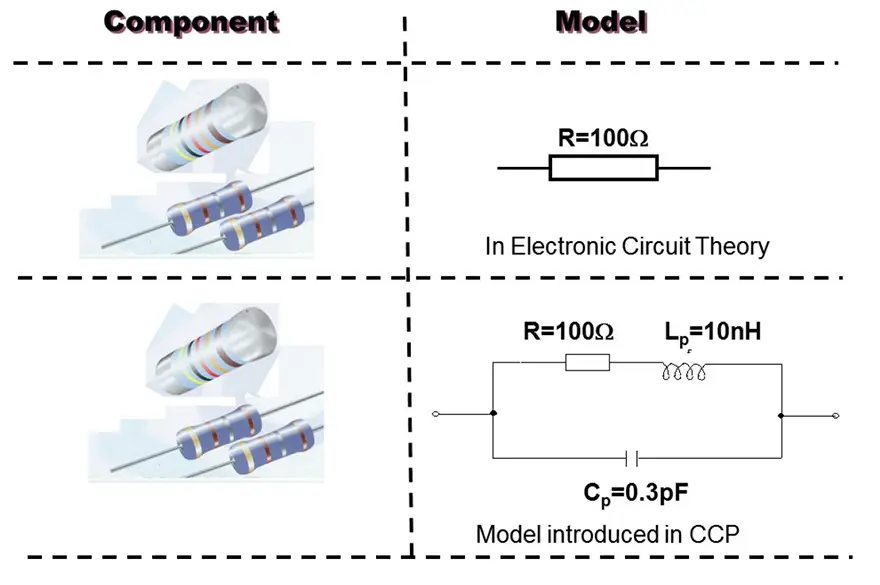

In our approach regarding Passive Components, even from the start we try to make the students realize clearly the difference between the physical quantity, for instance electric resistance and the corresponding passive component named “Resistor”. This approach, based initially on simple models permits to understand more deeply some very slight differences between different types of passives, see [2], [3]. In Fig. 1 is depicted this approach.

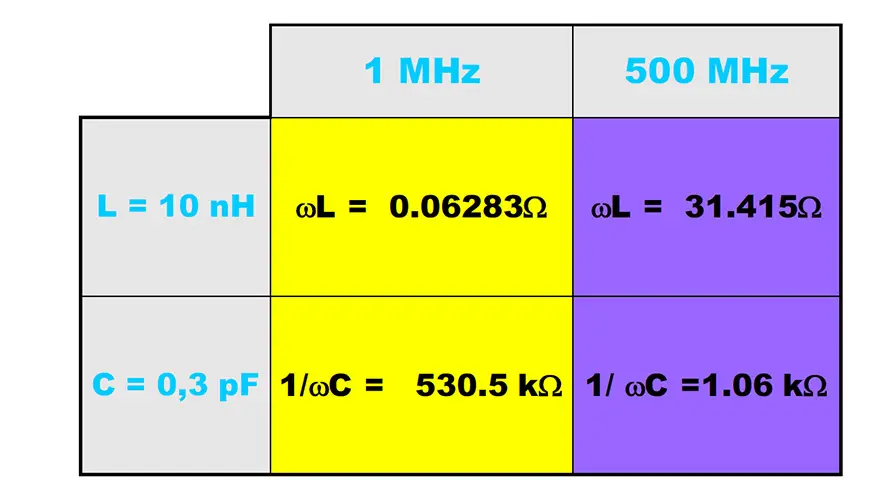

In the first semester disciplines related to electricity, the resistor is characterized only through its value. In our Passive Components lectures we introduced the simple model that includes the capacitive and magnetic effects that take place inside the resistor. Based on these, we can estimate the frequency behavior of resistors, by calculating the capacitive and inductive reactance. In Fig. 2, can be seen the results, based on values from Fig. 1.

The results in Fig. 2 are used to see firstly the way in which parasitic elements contribute to deviation from a simple resistance and secondly that the influence of parasitic elements is higher at higher frequencies.

We try to make the students understand the influence of constructive solution, but also of materials on parasitic elements. For instance, the spiral structure of a through-hole wirewound resistor leads to higher parasitic inductance in comparison with a flat SMD thick film resistor. Or, the ceramic used as substrate for a film resistor is certainly different from a ceramic used in type II capacitors. The influence of materials contained in a component on parasitic elements is more obvious when referring to capacitors. For instance, the losses are determined by dielectric, but also by the plates and terminals.

II. LABORATORY WORKS

Since the beginning of the new discipline, CCP (Passive Electronic Components) in 1990, it was considered necessary to use the time budget for practical activities associated with this discipline. The conditions at that moments have permitted the setup of three working places on which the students are permuted every laboratory class. This way of laboratory classes was used in the period 1990-1993

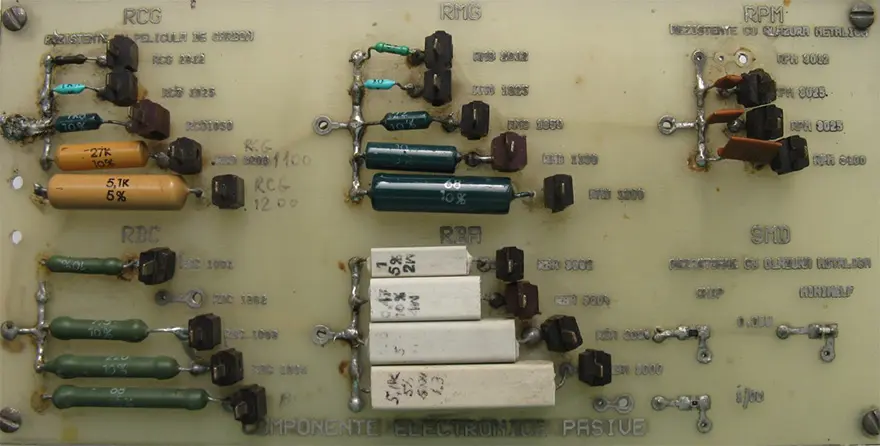

Starting with 1994 there was an upgrade to three or four simultaneously laboratory work places with support based on PCBs for Resistors and Capacitors, Thermistors, Varistors (SiC).For Inductors there were built air core inductors with different magnetic medium attached. All students are performing the same task in a laboratory class. It is to note the first time introduction of simulation with MathCAD on PCs. There was also available for students a printed Lab Guide support. Also for the first time in curricula the students in electronics had the possibility to hear about the SMD components, which were introduced in the Lab, but only mentioned, not yet studied. These SMD components can be seen at the right side of the board in Fig. 3.

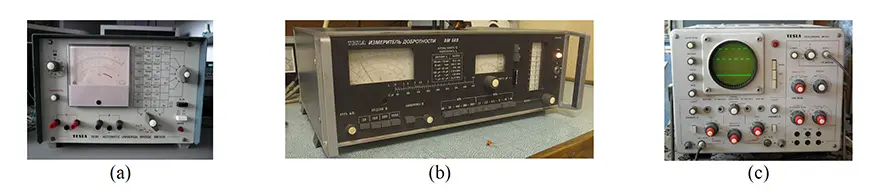

It is to mention that all the components except SMDs were manufactured at IPEE Curtea de Argeş. The measuring equipment was mostly manufactured by Tesla, built around 1980s, for instance RLC Bridge BM509, Q meter BM560, Oscilloscope BM463, see Fig. 4, and other general purpose analog and digital voltmeters.

b) Q-meter BM560, c) Oscilloscope BM463

The students had access to printed variant of catalogues, fortunately for the future there were edited in English. During the lab a lot of parameters were extracted from the catalogues. The measurements for resistors were limited to resistance value, for capacitors supplemental the loss factor was measured. For thermistors and varistors laboratory only the electric characteristics were measured, no thermal chamber was available at that time.

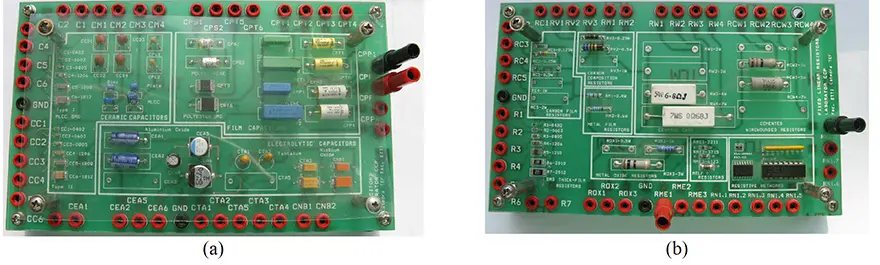

A major upgrade was performed in 2009, supported by the Faculty ETTI. This way, modern digital measuring equipment was purchased, the measuring support boards were re-designed on new PCBs including massively new SMD components. Resistive networks were also included beside ZnO varistors and miniature SMD inductors. The datasheets were first time interactively accessed from computers. It was previously intended an on-line access but it was not implemented. The supporting boards for capacitors and resistors are presented in Fig. 5 a) and b).

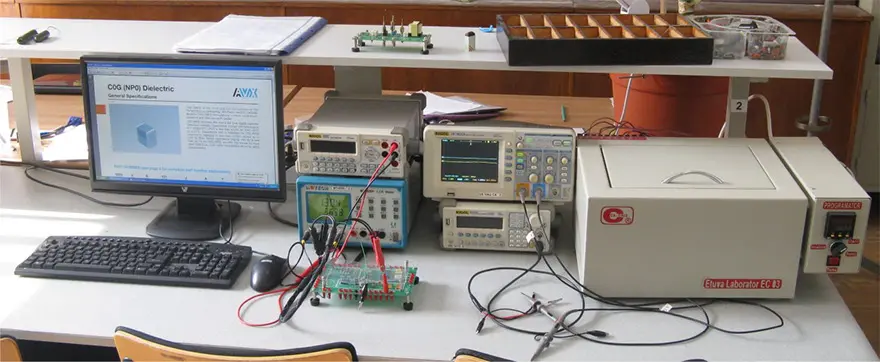

The modern working place, intended to accommodate up to three students is presented in Fig. 6.

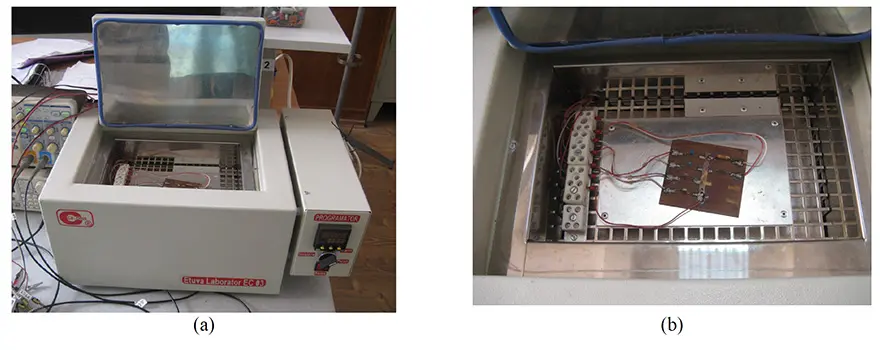

For the first time, temperature measurements were now possible, thanks to a miniature convection oven with controlled temperature, which was a custom design for our laboratory. This can be seen at the right side of the Fig. 6. In the oven we have placed two NTC thermistors, two PTCs and for comparison two fixed resistors, one carbon film and the other metal film resistor. The operating temperature range is between 50 ºC and 180 ºC, currently we stop at 150 ºC during the labs. We use a temperature step of 10 ºC, the set-up time for a new temperature takes about 10 minutes. This permits about 11-12 measuring points during a laboratory class and gives enough time for cooling of oven between two consecutive laboratory groups. More detail on the oven can be seen in Fig. 7.

a) overall view, b) detail of the DUTs

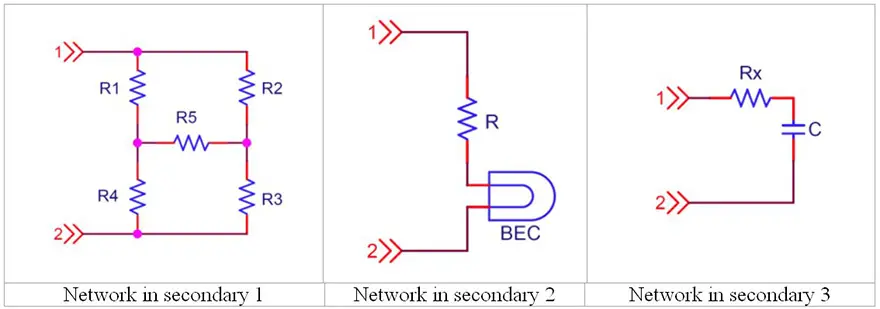

An important part of the laboratory mark consists in the homework. The students have as task to design a low power transformer with three secondary windings. The design of transformer is guided, being only a support for the main tasks. The load of transformer consists of circuits based on passive components. In some cases the students must choose the right components, in others the values are given and they should choose the right component from different families, in THT (Through Hole Technology) or SMD variant. In Fig. 8 is presented an example of requirements for the home work.

Subject for homework: LAB CCP

Task: Design a low power transformer that will have 3 secondary windings to feed 3 different resistive networks

Supplemental, the students must fill in a Bill of Materials (BOM) file, ready to be used for purchasing the components, using distributors acting in our country. The completion of BOM involves the responsibility for choosing the right components at the convenient price, we can call this a simulation of a real purchase activity.

III. ASSESSMENTS

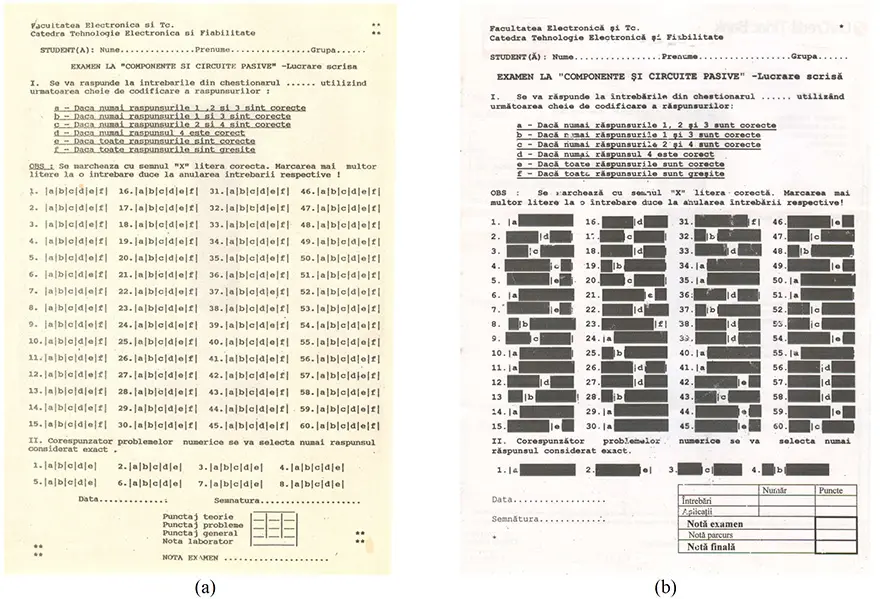

As in every activity, the evaluation of activity, the audit is necessary. During the time, we pass through different variants of students assessments. Between 1990 and 1993 the examination was oral, plus solving of application problems (calculus). Since 1994 we have implemented a multiple-choice test and the calculus was shifted in the laboratory class. The students received a blank formulary, see Fig. 9 a) together with a printed variant from six possible of questionnaires. There was no difference in content between the variants, only the questions and answers were shuffled. The check grid used was firstly from cardboard with punched holes, and later printed on transparent foil, as can be seen in Fig. 9 b).

The students have to choose the right solution from six possible from a to f, but these were related to possible correct combination of answers, which was written on the formulary.

As a remark, the same checking method is used today for the admission exam at UPB, including the formulary and check grid, the only difference is that only one answer of six is correct.

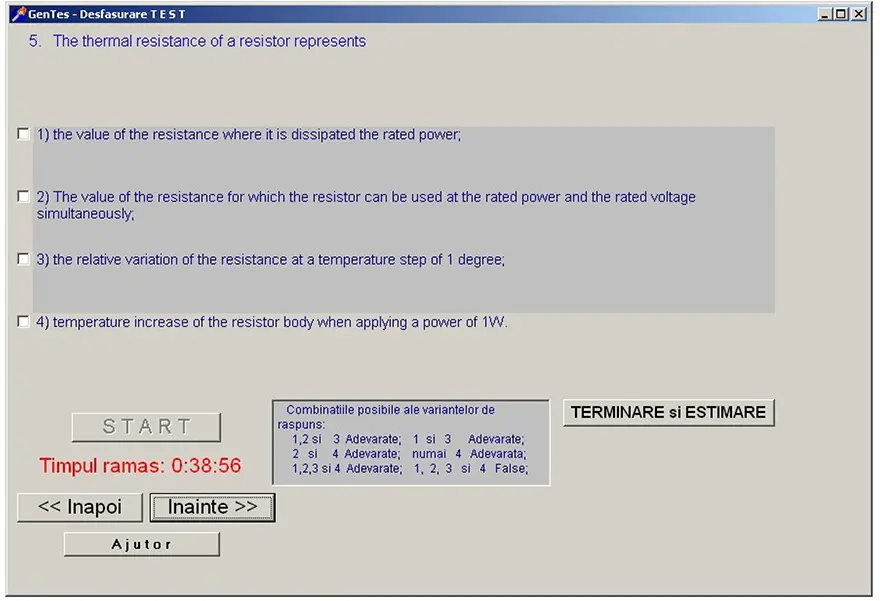

One of the assessment method with a high longevity was the program called Gentes, used from 2000 to 2014 with some interruptions in 2005 and 2006 when it was replaced with a Web based Test, see [4]. Gentes is an evaluation software, developed by our students, locally installed on PC. It is of type “multiple choice” with the question database being encrypted. From the multiple choice, only six combination of possible answers were possible, like in previous written variant of tests. A screenshot of Gentes is shown in Fig. 10.

One of the advantages of the Gentes in comparison to written form was the possibility to continuously upgrade the questions database with minimal effort. Anyhow, the test was difficult enough, but after so many years of use we have discovered a “leakage” of information, some students could trick the test. This forced us to make repetitive changes in questions database and in the test initial setup.

Since 2014 we moved our laboratories from old campus Polizu to actual campus Leu. The available space was shortened but the building is more appropriate for teaching activities. Accordingly to Faculty recommendations, the assessments were switched back to oral examination. So, there exists an exam note which includes theory subjects and one problem to be solved, the students have about 30 minutes preparation time and after that the examination is oral.

The percentage of Laboratory was before 60% and now is 50% from total points.

As a conclusion regarding the assessments, there are pros and cons of oral examination. As every oral exam, with different subjects for different students it is not 100% equitable, not all the students answer to same questions. On the other hand, a face to face discussion is the best method of evaluation on a specific topic. In the eve of online communication maybe the oral examination is anachronistic from student’s point of view. At this moment we don’t know in which direction is good to go further.

IV. RESEARCH IN THE FIELD OF PASSIVE COMPONENTS AND INVESTIGATION METHODS

The teaching activities, in the field of passives, were sustained by research in this field. The research was focused in the field of modelling and simulation, on one side and in the field of measurements and investigations, on the other side. We will present in the followings some measurements that are possible and were done in our laboratories, in some of them the students being also involved.

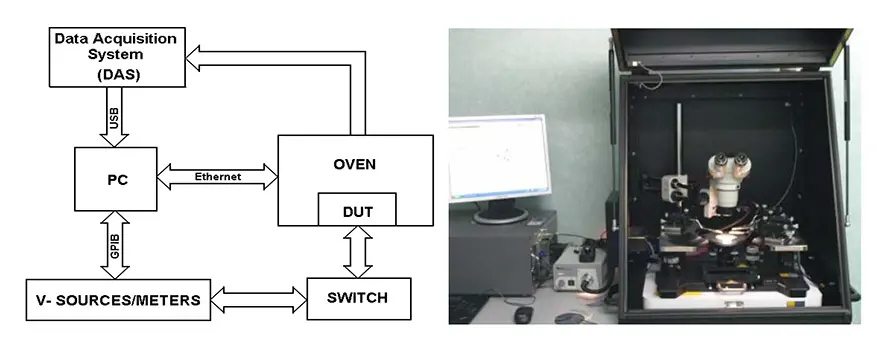

A) Complex Temperature Dependent Electrical Measurements

It is possible to perform I-V (T) and C-V (T) characterization for electronic devices based on 4200 SCS/C/ Keithley, completed with HP4140 pA meter, HP4275 RLC meter and Varian CP3800 oven, up to 450 ºC.

The C (V) feature of the system, intended for MOS transistor measurements can be used for passive components, for instance MLCCs, determination of RC values in parallel connections, determination of loss factors in some cases.

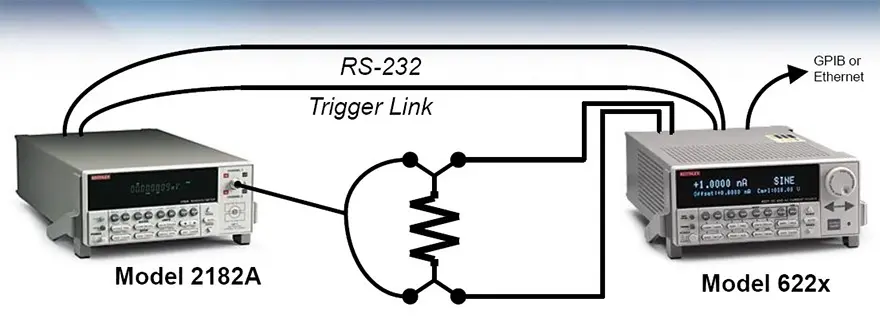

B) Precise low-resistance measurements

This measurements stand is based on tandem use of two Keithley equipments and it provides one of the best methods for measuring low resistances at low currents.

The source 6221, (we dispose of this variant), controls the 2182A Nanovoltmeter and calculates the readings expressed directly in ohms. The method called Delta reduces the thermoelectric offset and offers a very high accuracy.

C) Frequency dependent impedance measurements

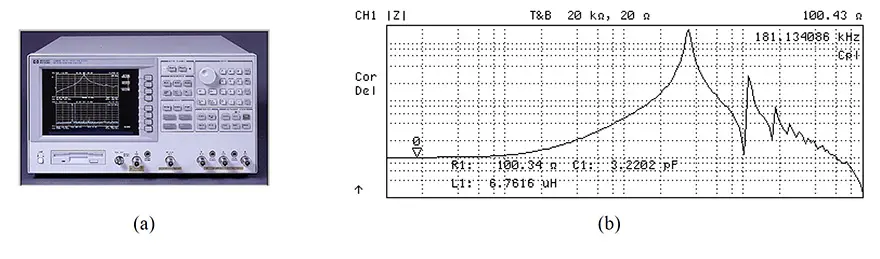

The Impedance analyzer Agilent 4396B permit us to investigate the frequency behavior of passive components. The 4396B is a performing equipment which operates as impedance analyzer (100 kHz – 1.8 GHz), network analyzer (100 kHz – 1.8 GHz) and spectrum analyzer (2 Hz – 1.8 GHz). It can measure practically all parameters related to impedances as: |Z|, qz, |Y|, qy, R, X, G, B, Cp, Cs, Lp, Ls, Rp, Rs, D, Q, and others. Supplemental, a DC bias voltage of ±40 V can be applied. The operation software of the apparatus can fit the data and associate it to RLC circuit models, a very useful feature in modeling of passive components. In Fig. 13 a) is shown the equipment 4396B and in Fig. 13 b) is shown an impedance modulus plot of a wirewound 100W resistor, showing the inductive character and multiple resonances of the device.

D) Infrared measurements

It is possible to perform temperature measurements using the FLIR SC640 IR Camera. Having a resolution of 0.06 ºC, auxiliary macro lens and appropriate analysis software can be used for passive components investigations. In Fig. 14 (a) it can be seen the camera and in Fig 14 (b) an IR picture showing the self-heating of SMD resistors.

For the future we intend to bring modelling topics of passive components closer to the students. In this perspective we will try to highlight the influence of material and physical structure of the component. And so, to assure a better understanding of the electrical, thermal, mechanical or technological properties. In fact, the topics of electronic passive components represent a very good environment where the students could understand the link (correlation) between material science and electrical, mechanical, thermal or technological behavior of the components. Such knowledge give possibility during the design process to identify the right component for a certain electronic product. The right component in the right place…and of course, with the smallest costs.

V. CONCLUSIONS

We hope that after the lecture Passive Electronic Components the undergraduate students will be familiarized with modern passive components. They will:

- Have the ability to choose the appropriate passive component for a specific calculation;

- Have the ability to do engineering calculations related to passive components;

- Have the ability to perform PSPICE simulation, including passive components;

- Have the ability to realize electric measurements, including temperature dependence of electrical parameters of components.

If these are good achievements, only the time will tell. Electronics is in continuous evolution, and so is the Passive Components domain.

ACKNOWLEDGEMENTS

We want to thank to all our previous co-workers that were involved in the development of the Passive Components lecture during these almost thirty years. We mention here Virgil Golumbeanu , Anghel Fleșchiu , Mircea Davidescu , Daniel Leonescu, Doina Moraru, Gabriel Popovici. In the same time we have to highlight the contribution of our Assistant Profesors, Rodica Negroiu and Niculina Draghici together with the technicians Silvia Ruba and Lizeta Marinescu and Doru Mihăilescu for their commitment to assuring in the laboratory, the high quality teaching environment.

REFERENCES

[1] Otto Zinke, Hans Seither, Widerstände, Kondensatoren, Spulen und ihre Werkstoffe, Springer-Verlag, Berlin Heidelberg, 1982.

[2] P. Svasta, V. Golumbeanu, C. Ionescu, “Electronic Passive Components Training Activity – Demand for Performance Electronic Package Development”, Informacije Midem-Journal Of Microelectronics Electronic Components And Materials, Volume 32, Issue: 4, 2002, p. 252-261.

[3] P. Svasta, N. Codreanu, C. Ionescu, V. Golumbeanu, “Electronic Packaging and Interconnection Techniques, Education at University Level – A Romanian Experience”, 51st Electronic Components & Technology Conference, ECTC 2001, Orlando, S.U.A., 29th May – 1st June 2001, pp. 1282-1289.

[4] Paul Svasta, Virgil Golumbeanu, Ciprian Ionescu, Norocel Codreanu, Daniel Leonescu, Marian Vlădescu, Dan Tudor Vuza, “Training Program in Electronic Passive Components Education”, 52nd Electronic Components and Technology Conference, ECTC 2002, 28 – 31 May 2002, San Diego, USA, pp. 780-786.

more 2nd PCNS symposium technical papers can be viewed and downloaded in pdf from EPCI Academy e-Proceedings:

Discussion about this post