Attendees of the 3rd PCNS Passive Components Networking Symposium that took place on 7-10th September 2021 in Milano, Italy discussed the latest news and trends in passive components. The main theme of the conference was RELIABILITY & SUSTAINABILITY of PASSIVE COMPONENTS that also covered MATERIALS development and PROCESSES.

3rd PCNS was attended by 50 live attendees and 25 virtual attendees from 16 countries including 12 European Countries, Israel, USA and Korea. Theme of the conference “Reliability and Sustainability of Passive Components” was elaborated in workshop on life cycle assessment and addressed by keynotes, invited papers and hot panel discussion. Twenty four full technical papers were presented during two and half PCNS event days covering wide range of passive components including capacitors, resistors, inductors, integrated passives or passive sensors.

The most discussed items that may influence passive components design and selection guide during the next decade can be summarized in three chapters:

- Reliability

- Sustainability and Life Cycle Assesment

- Materials

Education, and how to increase interest in passive components from engineers, students, teachers and complete supply chain was the other topic widely discussed during the PCNS program and social networking.

Reliability

Automotive application sector has become one of key drivers for passive component development. Newly introduced components are more and more designed to be compliant with AEC-Q200 passive component automotive standard requirements – even if the end application is not necessary related to automotive segment. The other non-automotive sectors on the other hand tend to more and more accept automotive components level for broader use.

Is AEQ-200 Becoming the Ultimate Reliability Standard? was title of Keynote from Alexander Gerfer; CTO of Würth Elektronik to open the hot topic panel discussion.

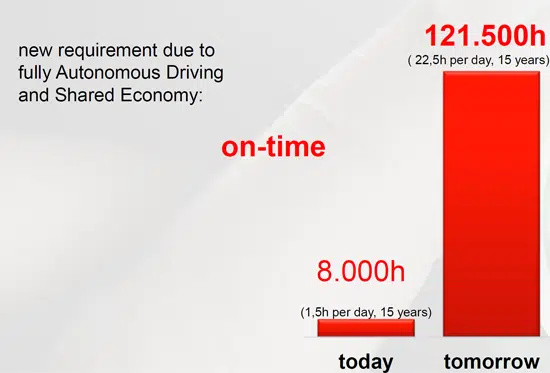

In many applications AEC-Q200 requirements are sufficient declaration of reliability – but is this relevant in all environments and for future requirements? Most of the time car is in OFF mode in garage for its life today, but autonomous driving and shared economy may raise the requirements significantly – from 8 000 hrs to above 120 000 hours within 15 years.

There are number of other applications within industrial segments that require 24/7/365 operations at constant high temperature and high humidity requirements where 2000 life tests at corner specifications according to AEC-Q200 requirements may not be sufficient – unless there is a deeper understanding of basic physical processes and trusted life models available.

New space in aerospace also carefully evaluating automotive level parts for use at non-critical flying hardware applications, but requirements may be different. It mostly has to operate reliably at continuous operation, but at “component benign” environment without oxygen and humidity. On the other hand the components must survive extreme launch vibrations, be free of out-gassing with sufficient radiation hardness (mostly no issue for passives).

Novel dielectric, magnetic materials and constructions are today working with much higher electrical fields, power densities but also utilizing purer, nano-engineered, advanced materials. Do we have relevant physical models available?

understanding the components failure mechanism(s) will be the insider of future designs

Sustainability and Life Cycle Assessment

Workshop titled “Characterisation Techniques and Life Cycle Assessment of Materials Involved in Passive Components” presented by Giovanni Dotelli; Politecnico di Milano and Luca Primavesi; Itelcond opened next important topic for the next decade design of non only passive electronic components.

Life sustainability – Life Cycle Assessment including environmental fingerprint & recycling may be the next complex challenge that may drive selection of new materials, processes or re-design of current products.

Legislation with emphasis on life cycle assessment and lower environmental load products has been under preparation including environmental labels. In 2019 the EN 50693 standard specifies the process and requirements on how to conduct life cycle assessment in the context of environmental declarations. This document provides common rules for:

- life cycle assessment (LCA),

- the LCA report;

- the development of product specific rules

Examples of Life Cycle Assessment of Passive Components

- Smith, L., Ibn-Mohammed, T., Koh, S.C.L., Reaney, I.M. Life cycle assessment and environmental profile evaluations of high volumetric efficiency capacitors (2018) Applied Energy, 220, pp. 496-513. DOI: 10.1016/j.apenergy.2018.03.067

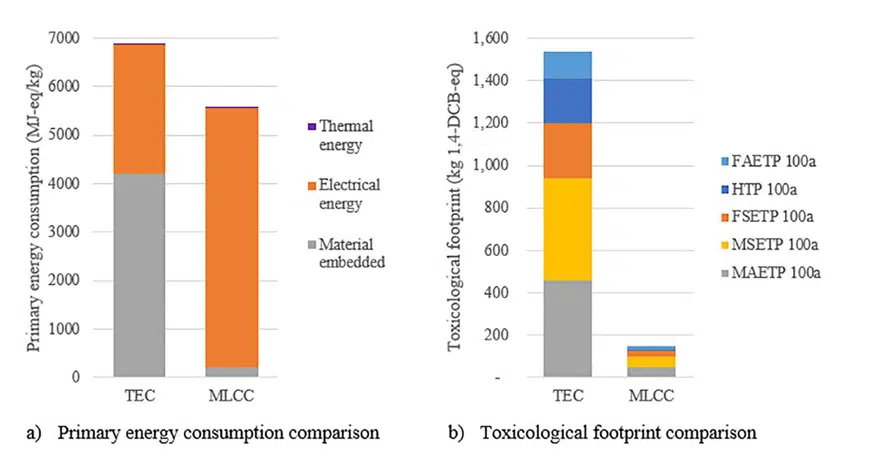

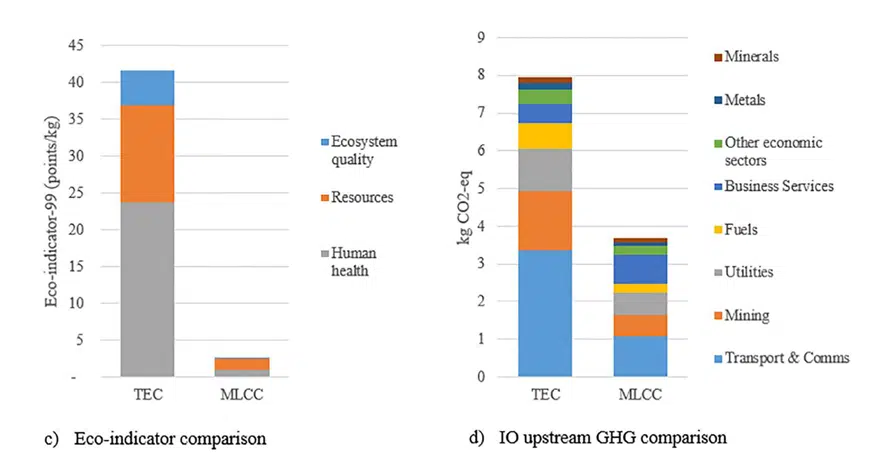

This example presents a methodologically robust lifecycle assessment (LCA) of two representative capacitors: Tantalum Electrolytic Capacitors (TECs) and Multilayer Ceramic Capacitors (MLCCs) to evaluate and address its environmental aspects. The impact assessment shall support the end electronic hardware product life cycle evaluation and optimization.

Impact assessment of Tantalum Electrolytic Capacitors (TEC) vs MLCC Ceramic Capacitors; source: 1) Smith et col., DOI: 10.1016/j.apenergy.2018.03.067

2. Cossutta, M., Vretenar, V., Centeno, T.A., Kotrusz, P., McKechnie, J., Pickering, S.J. A comparative life cycle assessment of graphene and activated carbon in a supercapacitor application (2020) Journal of Cleaner Production, 242, art. no. 118468, DOI: 10.1016/j.jclepro.2019.118468

The work above is an example of LCA study on three graphene production routes: electrochemical exfoliation of graphite rods, graphite chemical oxidation and subsequent chemical or thermal reduction and chemical vapour deposition (CVD) to evaluate life cycle of supercapacitors manufactured with different graphene and activated carbon active materials.

Life Cycle Thinking is about going beyond the traditional focus on production site and manufacturing processes to include environmental, social and economic impacts of a product over its entire life cycle

www.lifecycleinitiative.org

Materials

materials are becoming the central point for many aspects of future designs

(i) understanding of material properties, its basic physics mechanisms are the key for failure mechanisms assessment and reliability predictions. Component evaluation based on relatively short testing (such as 2000hrs as per current AEC-Q200) may not be satisfactory for certain applications including automotive segment.

(ii) component design will have to evaluate complete supply chain and material selection in order to asses its complete life cycle and reduce its environmental footprint.

(iii) nano-material science may be necessary to develop completely new generation of modern materials / respectively re-design of current existing components to achieve aspects (i) and (ii).

Education – Passive Component Engineers Wanted

The passives are considered as “simple” components out of prime interest for many students, teachers, engineers, designers … however in potential consequence 70% of PCB board space today are occupied by passives.

task to the whole passive component industry is to promote passive components as the interesting topic for students to engage – with plenty of scientific challenges to address and solve.

As an example: Capacitors may present quite challenging structure under closer look – not as simple as just Metal-Insulator-Metal structures. Dielectrics are often metal oxides that create semiconducting thin sub-oxides in the transient zone, thus in reality we are faced with M-S-I-S-M systems that may be more complicated than pure semiconductor and crystalline structures. With trend to lower working voltages and higher electrical field (high CV capacitors) the insulator layer are thinner and impact of transient zones is becoming dominant to the capacitors structure. Capacitors are many times used across the whole voltage and SC may cause malfunction of a complete system, thus it is on of the critical component that defines the end device over all reliability.

EPCIA European Passive Components Industry Association introduced EPCIA Student Award to grants all students – graduate and PhD candidates – the possibility to attend a conference and present their thesis on passive components to an expert audience. 3rd PCNS was pleased to host 2021 EPCIA Student Award Ceremony with two students awarded.

In Conclusion

Based on 3rd PCNS papers and discussions we (as a passive industry) are in the phase where deeper understanding and research activities are needed to initiate next step-up in design towards future components. Closer co-operation within a supply chain and also academia on further research of new materials, processes and life assessment is becoming more and more important for sustainable growth.

This include also challenge to change way of thinking about passive components – attract young students about its research tasks and attractiveness to study at universities.

more than 50% of the PCNS attendees ranked 3rd PCNS as 10 of 10 top score – extremely likely recommendation for others to join.

Book your calendar: 4th PCNS in September 2023 to be hosted by SDU University in Denmark

About

PCNS Passive Components Networking Symposium is a bi-annual international symposium organized by EPCI European Passive Components Institute in co-operation with an European university 3rd edition of the PCNS Passive Components Networking Days Symposium is hosted by Department of Chemistry, Materials and Chemical Engineering “Giulio Natta” and Department of Electronics, Information and Bioengineering of Politecnico di Milano