source: ESA ESTEC; ESA SPCD 2018 Symposium

EPCI e-symposium library article

ESA component engineers Dr.Denis Lacombe and Dr.Léo Farhat are introducing their presentation on space relays failures and lessons learnt.

published by EPCI under approval of ESA SPCD 2018 organizing committee.

Title: Relays Failures Occurring & Lessons Learnt

Author(s): Dr.Denis Lacombe and Dr.Léo Farhat

Organisation(s): ESA ESTEC, The Netherlands

Symposium: ESA SPCD 2018

Reference: Lessons Learned and In-flight Experiences

ISBN: N/A

e-Sessions Applications: Aerospace

e-Sessions Scope Components: Relays, Inductors

e-Sessions Topics: Technology, Materials, Quality & Reliability

INTRODUCTION

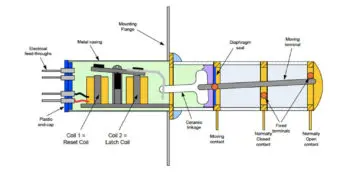

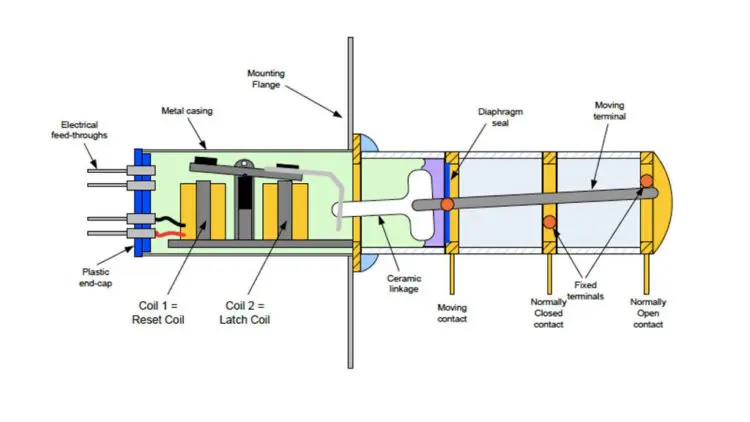

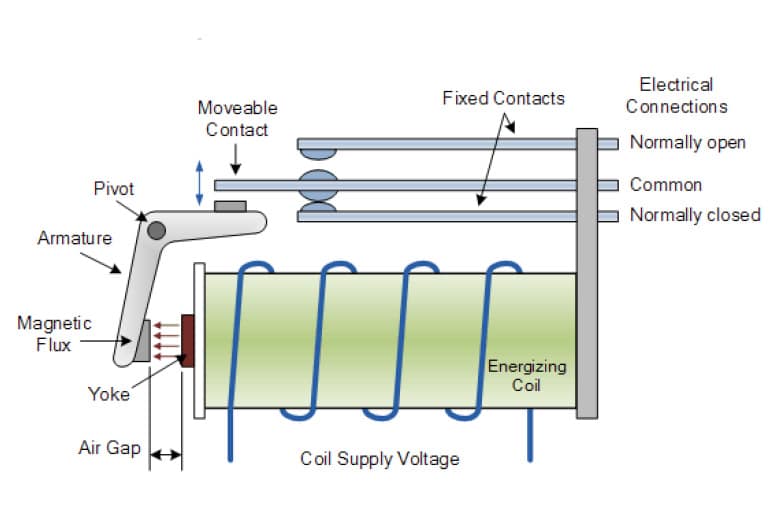

“An electromechanical relay is an electrical switching device. Its function corresponds to a mechanical switch, which is electrically actuated. The main advantages of electromechanical relays are the electrical isolation of the driving system and the load side, the insulation resistance of open contacts, as well as the low resistance of the closed contacts.”

- Complex device with many pieces’part (40 to more than 100)

- Risk of losing the defect

- Interest of new methods (Xray, tomography, FIB)

Root cause of observed failures

On 13 observed failures:

- 3 are due to bad commands

- 1 is due to bad handling of the relay (soldering)

- 5 mechanical stress are either the cause or a contributing factor

- 8 real failures of the relay

5 (≈40%) of the observed failures may have been avoided if better knowledge of relay was used.

… see more at the full presentation link below…

CONCLUSION

ESA alert recommendations

New procurement of ESCC qualified TL26 relays:

- parts with DC1611 or later shall be preferred.

- Stock Parts shall be 100% screened by five (5) Monitored Temperature Cycles (-65°C/+125°C) followed by electrical tests at 25 °C as per table 2 of ESCC Detail Specification No. 3602/002.

- Mounted parts with lot Date Codes identified as Category 2 in Annex 3 shall be subjected to thermal cycling as specified

below:- Minimum 5 cycles

- Minimum delta temperature of 70°C measured on the relay case. For example, thermal cycles at board level between -20°C to 50°C, Lower delta temperature values are not relevant

- Duration and transition rate of cycles are not considered as important parameters.

- The relay shall be switched at high and low temperature during the last cycle of the sequence.

Lesson learnt and recommendations

- Bad command signal: do not use latch and reset voltage limit

- Beware of mechanical stress: relay are more sensitive in certain direction then try to use this information to place the relay

- No switching failure may be intermittent: implement the possibilities to send command signal several times

- Failure analysis is difficult and need to be carried with care using up to date investigation methods

see the full presentation here: